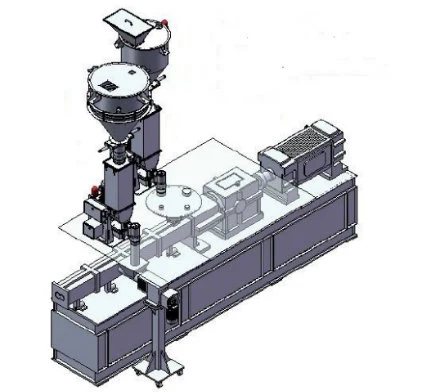

Multi Component Gravimetric Feeder/Loss in Weight Feeder Machine

Welcome to Nanjing kairong-Machinery Company Kairong group , headquartered in Nanjing, China, is a global manufacturing

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | GBL-SS72 |

| Max Feeding (mm) | 750 |

| Capacity(t/h) | 400-600 |

| Motor Power(kw) | 20~25 |

| Installation Slope | 0 |

| Chute size(mm) | 6000×1300 |

| Overall Dimension | 6082×2580×2083 |

| Color | Customer Choice |

| Transport Package | Wooden Case |

| Specification | CE ISO |

| Trademark | GBL-SS72 -kairong |

| Origin | Nanjing |

| HS Code | 87265100 |

| Production Capacity | Depends |

Product Description

Welcome to Nanjing kairong-Machinery Company

Kairong group , headquartered in Nanjing, China, is a global manufacturing and trading company in the field of high-performance plastics and rubber processing equipment , extrusion solutions, masterbatch and compounding, etc. Its unit Nanjing Haisi Extrusion Company is a prefessional manufacturer of twin screw extruder, single screw extruder ,two stage extruder and its related auxiaries. We tailor solutions from raw materials, materials processing equipment, to injection for different customers. Each Kairong solution is designed , manufactured, and commissioned by experienced teams of professionals engineers and aftersales staffs.

Kairong group offers raw materials, Mixing and conveying unit, extrusion technology, recycling unit, profile extrusion etc. We offer whole plant ,even turnkey solution to meet different customers' requirements.

Customized according to your requirement

Details:

1) Screw diameter : 71mm. L/D= 36:1/40:1/44:1/48:1

2)Main drive motor :AC 132kw,speed regulated by ABB transducer inported from switzerlad

3)Screw rotary speed:50~600rpm

4)Screw shaft is made of high-strength alloy 40CrNiMoA.

5)Lenght of each barrel is 290mm,totally 9 pieces of barrels

6)The 1st barrel is the main feeding vent,the 5th is for degassing,8th is vacuum section,and the others are closed barrels.

7)Casting copper heaters for 2.3th barrels.The others are equipped with casting aluminum heaters,All heating power:~50 kw

The extruder figure:

Feeding Degassing Vacuum

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Four hinge style die section |

8)Reducing and distributing gearbox:

The gearbox reduces the motor speed to the speed of the screw shafts and distributes it to the 2 output shafts,

this gearbox output torque can reach 4.8T/A3

The gearbox consists of:

l Involute gear teeth couplings between the output shaft and screw shafts

l Integrated thrust bearing assembly,radial bearings of the output axis are NSK products

l Bottom part of casing designed as oil sump

| Mode | Diameter (mm) | L/D | Screw rotary speed (r/min) | Motor power(kw) | Torque(N.m) | Capacity(kg/h) |

| TSE-20 | 22 | 32-44 | 600 | 5.5 | 43 | 1-10 |

| TSE-30A | 31 | 32-48 | 500 | 11 | 105 | 5-30 |

| TSE-30B | 31 | 32-48 | 600 | 15 | 119 | 5-40 |

| TSE-40A | 41 | 32-52 | 600 | 15 | 119 | 65-110 |

| TSE-40B | 41 | 32-52 | 400 | 22 | 263 | 90-150 |

| TSE-52B | 51.5 | 32-64 | 600 | 75 | 597 | 225-250 |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-300 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-550 |

| TSE-75D | 71 | 32-64 | 600 | 220-250 | 1990 | 500-1000 |

| TSE-95A | 93 | 32-64 | 500 | 250 | 2387 | 600-1000 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 800-1200 |

| TSE-135 | 133 | 32-64 | 500 | 750 | 7162 | 1500-2250 |

- Feature

- Modular design, safe, simple, and reliable use

- Components: SFE/TFE feeder module, TSP weighing module, TVH dosing module, EC-LWL control module

- Operation and display through Sonner M250 industrial computer

- Capacity: 0.3 to 2000 kg / h for free-flowing material, 0.06 to 1500 kg / h for non-flowing material

- Accuracy: ± 0.1 to 0.25 %

- Application

- Processes: polymer compounding (polyolefins modification, engineering plastics, masterbatch, composites, polymer alloys), plastics extrusion (cable), food processing. ST11/SS23 design for small scale feeding and laboratory testing

- Handled material: free-flowing (pellets and granules) and non-flowing (flakes, regrind and powder)

- Accessories

- ISVD70 slide valve:Aluminum alloy, anti- oxidation treatment,Stainless steel slide plate

- IBVD100 butterfly valve: cast iron body, stainless steeldisc plate

- Intergraded compressor air driven device 0.6-0.8 Map

- Inlet/outlet soft connector

- Downspout parts

- Air-vent filter

- Standard Installing fram

- Drawing

Other applications:

1, Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC, POM, PPS, PET, etc.

2, Polymer blending:blending of PC/ABS, PA/ABS, CPE/ABS, PP/EPDM, PA/EPDM, PP/SBS,etc.

3, Incorporation of Fillers: Caco3, Talc, TiO2, carbon black,filled PE, PP, or EVA, etc.

4, Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE; radiation-crosslinkable compounds, optical fibre protection compounds, heat-shrinkable polymer compounds.

5, Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes, tobacco filter compounds, etc.

6, High Concentration Color Masterbatches: PE, ABS, PS, EVA, PP,etc. with high concentration of pigments and other processing aids.

7, Masterbatches with Flame-retardants: PE, ABS, PS, EVA, PET, PP, etc. with flame retardants and other additives.

Characteristics:

1, New high speed and torque gear box ,type B. Key bearings of NSK products.

2, Euro-style barrels are made of high quality steel with bimetallic liners, whose refux refrigeration channel makes temperature difference in C areas smaller.

3, Screw elements and kneading blocks are designed accurately by precise process, agile combination,and interchangeability, to fulfill efficient self-cleaning, transmission , compounding and pressure built-up.

4, Water cooling strand pelletizing system insures high granulating efficiency.

Protection measure and cooling method:

1. Torque of each screw reaches 800N.m~1400N.m

2. Linkage protection of motor adopts high quality nylon pin to make sure of safety and efficiency.

3. Side tubes of water-cooling system are of high quality copper material.

Besides the twin screw extruder, kairong supplies all the auxiliary machines and spare parts

why choose us?

1.Kaironggroup is an integrated company with research and development production, sales and service departments.

2. 6 Years of experience in packaging machinery.

3. With research and development team, we welcome OEM and ODM orders.

4. Strict QC process to make sure each product with good quality.

5. Various equipments to meet your need.

6. Unique business philosophy brings reliable quality and considerate service

Payment optional

- 30% TT is down payment as deposit, and 70% is paid before shipment.

- 30% TT is down payment as deposit, and 70% by irrevocable L/C at sight.

- 100% irrevocable L/C at sight.